Weighing Booth (Sampling Booth) is a clean space where the air flow is blown from top to bottom and the suspended particles in the air due to weighing or sampling are directed and absorbed towards the filters. the user and the product are protected from contamination. Also, due to the creation of negative pressure inside the chamber, particles are prevented from penetrating outside the chamber.

Weighing Booth (Sampling Booth) Property

The body and legs are made of 1.5 mm thick iron sheet with electrostatic powder paint/ The body and legs are made of acid-proof stainless steel sheet.

Equipped with a second movable dark manual door to use the UV lamp at the same time as the staff is present

Covering more than 90% of the internal cabin roof by the main filter to increase efficiency

French HEPA filter according to EN1822 certified standard

Efficiency of 70% filtered air into the hood and 30% into the laboratory

Full-time, 20-minute UV control with a 20-second delay

Glass alarm to maintain standard air circulation

FATECH brand PLC electrical system

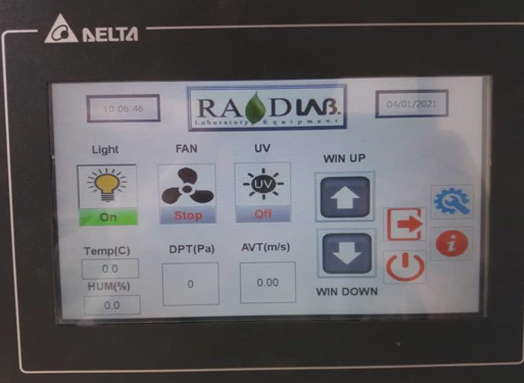

7 inch color touch control panel with easy and advanced use

- Demonstration of UV lamp operation

- Show the function of the filter

- Display, time and date

Tempered glass and electric lift

One-piece steel work surface (seamless)

UV lamp

Filters can be changed by the user

Special wheeled base with lock

Vertical ventilation system

Strong ceiling lighting

There are two sockets in the door

Weighing Booth (Sampling Booth) components

This hood includes the following components.

- French HEPA filter according to EN1822 certified standard

- Glass alarm to maintain standard air circulation

- 7 inch color touch control panel with easy and advanced use

- Has a pressure sensor to display the pressure difference between the two filters (pa)

- Special wheeled base with lock

- There are two sockets in the door

- Strong ceiling lighting

- UV lamp

Weighing Booth (Sampling Booth) standards and facilities (sampling)

This hood has the following features and standards:

- Pressure difference sensor of two filter heads, flow, temperature and humidity

- Preventive maintenance instructions

- Manuals

- Construction plans

- Electric maps

- Body material certificate

- Factory Test (FAT)

- Testing at the buyer’s factory (SAT)

- All documents and documents DQ, IQ, OQ

Weighing Booth (Sampling Booth) screen

This BSC control system works with a color touch screen and the screen shows the real parameters of the environment and monitors the emergency situations. The system includes remote access for customer service support. If needed, it is possible to connect to an additional device for storing and transferring production data.

Weighing Booth (Sampling Booth) screen

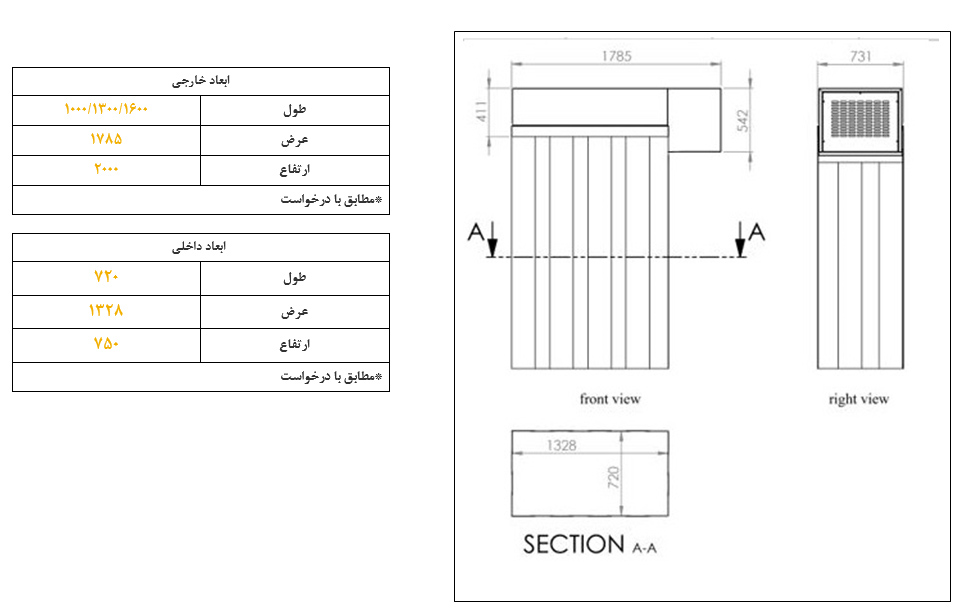

Shape of maps:

Schematic map of distribution room

Reviews

There are no reviews yet.