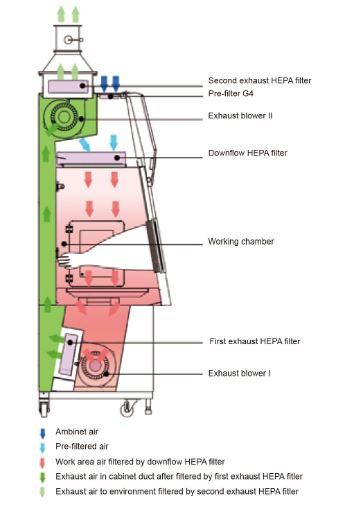

Class III Biosafety Cabinet is totally enclosed and gas-tight with ULPA/ HEPA filtered supply and exhaust air. Work is performed with long-sleeved gloves. The cabinet is kept under negative pressure of at least 120Pa, and airflow is maintained by a dedicated exterior exhaust system. It can protect the operator, product and environment. The Biological Safety Cabinet Class III is designed to provide the highest level of containment when working with hazardous materials involving highly infectious microbiological agents in BSL-4 Cabinet laboratories. These gas-tight enclosures protect the operator, the environment as well as the work in progress.

Features:

- Long-life HEPA / ULPA filters for supply and exhaust (per IEST-RP-CC001.3) with 99.997% efficiency for particle size between 0.3 to 0.5 microns

- One pair of 800mm CSM gloves

- One pass box chamber.

- Negative >120 Pa

- Covering more than 95% of the roof of the internal cabin by the main filter to increase efficiency to create class A cleanliness

- 100% efficiency of filtered air into the hood and 100% into the laboratory

- negative pressure of at least 120Pa.

- UV control full time and 20 minutes with a delay of 20 seconds

- Jacket material: Iron sheet with the powder coating / STANLESS STEEL

- Glass alarm to maintain standard air circulation

- PLC electrical system with touch control panel with easy and advanced use:

- Pressure sensor to display the differential pressure (pa)

- Show the operation of the UV lamp

- Show the function of the filter

- Time and date display

- Filters can be changed by the user

- Special wheeled base with lock

- Laminar flow 0,45 m/s ±20%

- Vertical ventilation system

- Strong ceiling lighting

- Two outlets with doors

- One-piece work surface

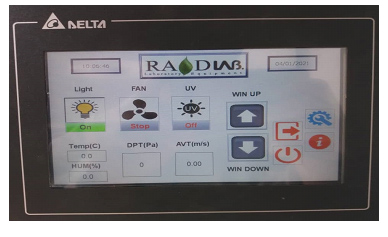

Display class 3 hood

Parts:

- Visual and acoustic alarm

- Electrical Outlets

- HMI panel

- HEPA filter

- Front window

- UV lamp

- Wheels

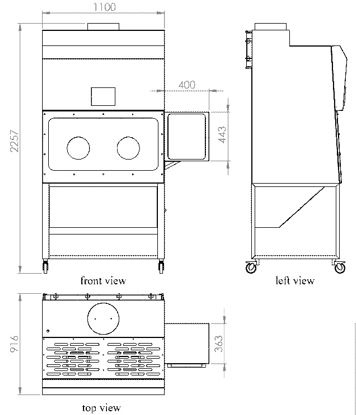

Front view class 3 hood laminar

Standard and Option:

- Temperature and humidity sensor

- Velocity sensor for laminar flow

- One pair of 800mm CSM gloves

- Pressure sensor

- The company will provide the following documents, and other documents required by the customer will be provided as options.

- Operation Manual (OM)

- Maintenance Manual (MM)

- Pipes & Instruments Drawing (P&ID)

- Layout Drawing

- Electric Drawing

- Instruction for the Main Parts

- Material Certificate

- Factory Acceptance Test (FAT)

- Site Acceptance Test (SAT)

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Design Qualification (DQ)

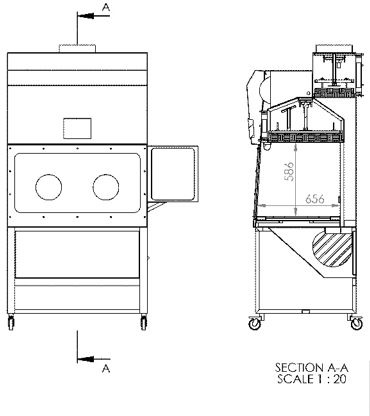

Information class 3 hood

Display (HMI PANEL) :

This BSC control system is operated with a color touch screen. The screen displays the actual parameters of the environment and monitors emergency statuses.

Shematic class 3 hood

Drawings:

| Inside dimensions * | |

| Width | 656 |

| Height | 586 |

| LENGHT | 1097 |

| * Adaptable on request | |

Dimensions in mm

| Outside dimensions * | |

| Width | 916 |

| Height | 2257 |

| LENGHT | 1500 |

| * Adaptable on request | |

Reviews

There are no reviews yet.